JT: Digital Transformation Enabler

Second prostep ivip jt day

What a day! 180 experts and decision makers followed prostep ivip’s invitation, received information about status and strategies with regard to the industrial application of JT and where deeply impressed.

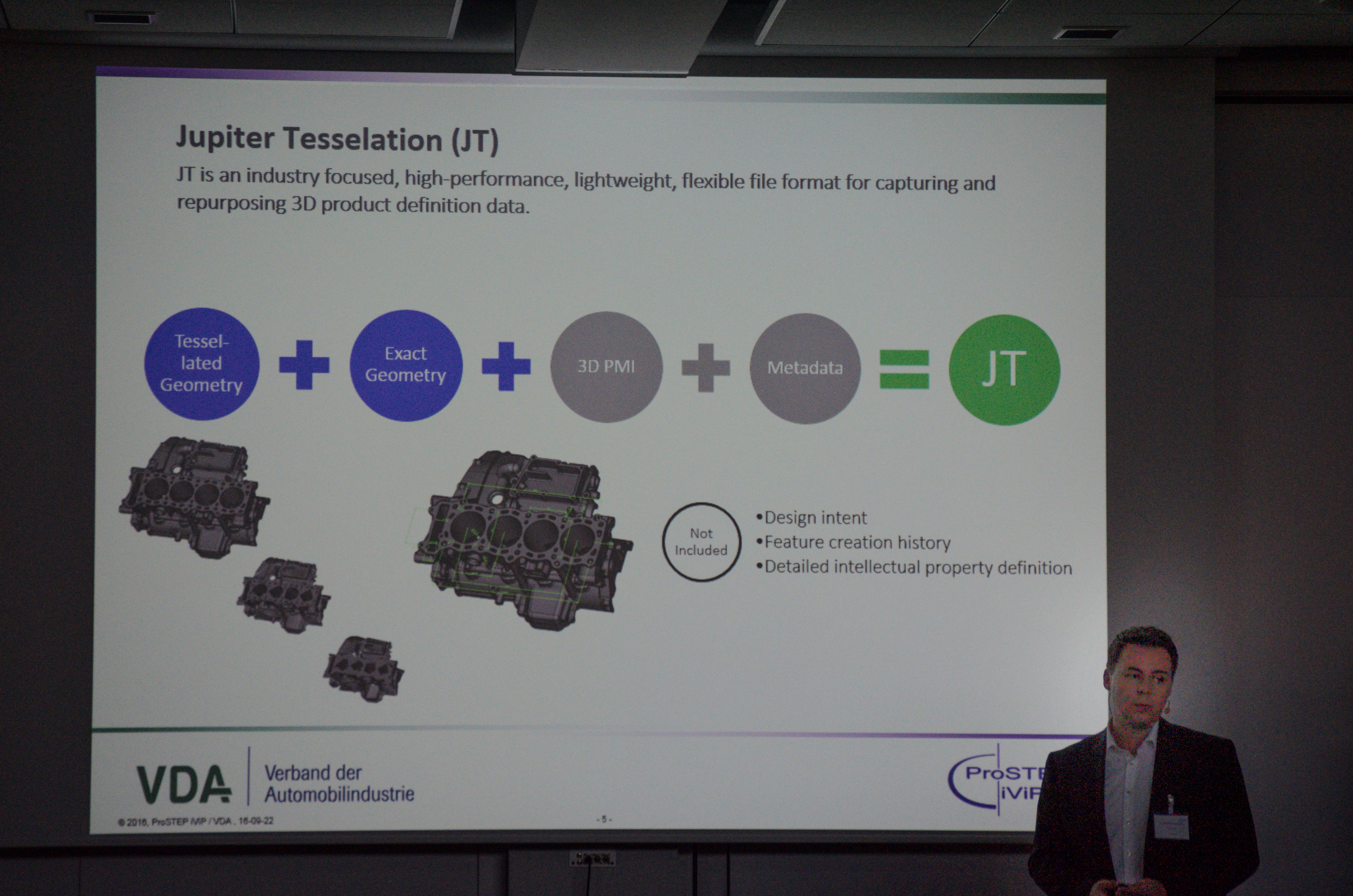

Right at the opening of Rudolf Dotzauer from Continental and Dr. Sebastian Handschuh from Daimler, the two chairs of the prostep ivip / VDA projects JT Workflow Forum, JT Implementor Forum and JT Benchmark, it was clear to everybody, that this event will have signaling character. JT is in productive application. Far more than 300 million JT-Files are managed in productive applications. And in collaborative scenarios approximately 75% of all 3D-data could be exchanged via JT. But that’s not the end of the road, that’s just the beginning, as the three keynote speakers stressed.

Thomas Buck, CIO Continental Automotive, worked out Continental’s four clusters for digital transformation: Digital Business Model, Smart Factory, Digital Workspace, and Digital Efficiency. How serious Continental drives this forward, Thomas demonstrated in a Live-VR-Collaboration-Demo. Within the overall context, JT is seen as the carrier for hardware information on any type of device.

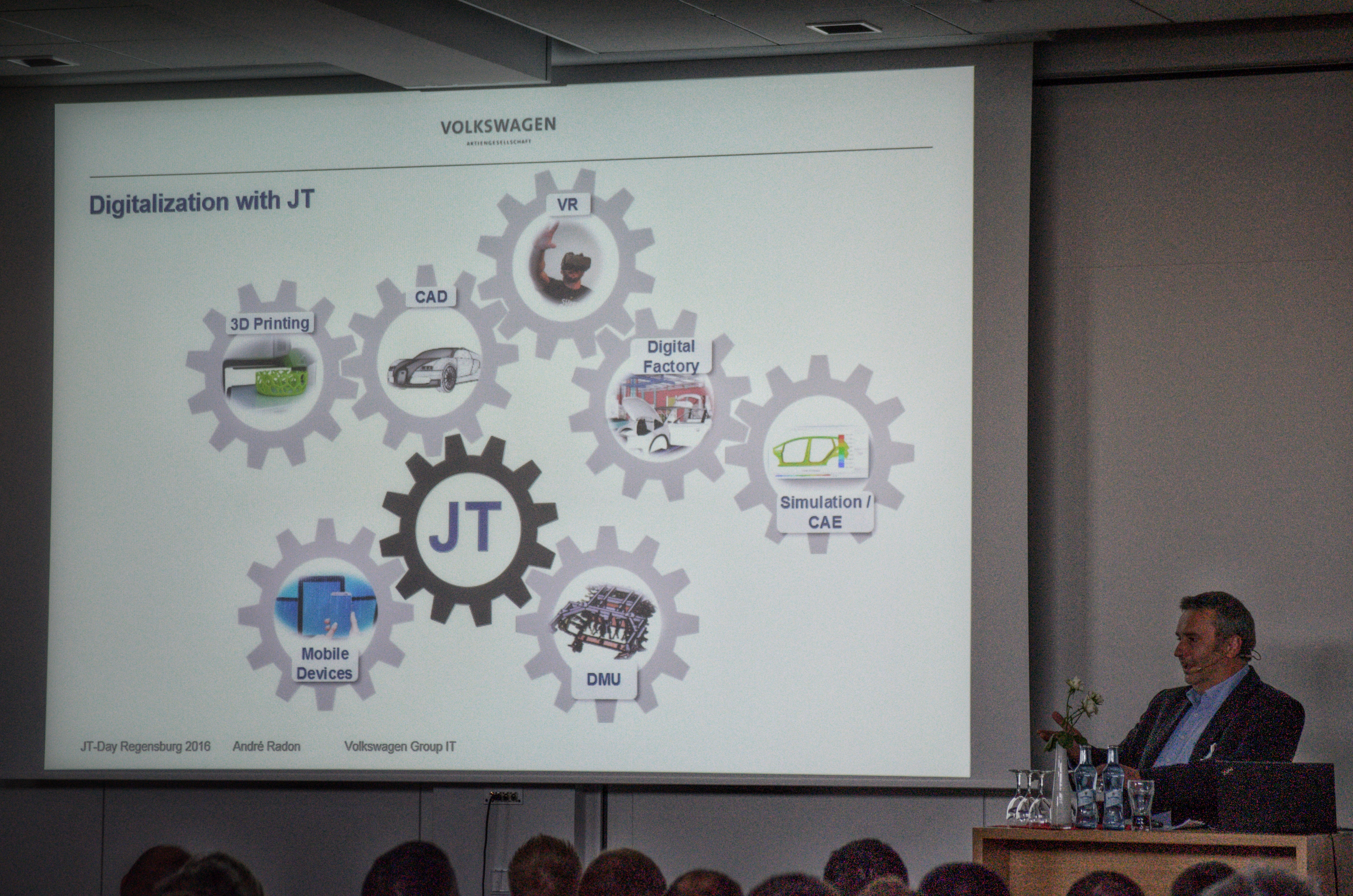

Volkswagen’s Head of Engineering IT, André Radon, underlined this and postulates that digitalization will completely change the business model of automotive manufacturers. And this will not be within the next 50 years, but in 5. Silos, not only in engineering, but also in controlling, sales, production etc., will be teared down, and “things” will be connected. Participants felt a strong wind of change.

It’s neither the strongest that survives, nor the most intelligent that survives. It’s the one that is most adaptable to change. Charles Darwin

For realizing product-related information flows, JT is the driving gear. With regard to this, André gave impressive examples. The introduction of the use case “Configurable Electrical System” was a world premiere. Thereby, JT is directly derived from KBL/VEC data through an automated conversation process. And by this, André also draw the logical link toward yesterday’s VEC Day.

Dr. Siegmar Haasis, Head of Engineering IT at Daimler, took up the words of his predecessors and sums up what is necessary for the already started digital transformation: access to information, the new oil, and performance. Or simply: Speed! Speed! Speed!

It’s inevitable for a global player like Daimler to strengthen its strength, to combine technologies and to interpret things in new, innovative ways. Regarding this, JT is not a format, it’s an enabler. Until 2020, Daimler e.g. envisions to realize complete information flow based on JT – with geometry, material definition, equipment, appearance and variation centrally available for all downstream processes.

In the following presentations Ingo Nuccio from Bombardier presented the application of JT during heavy railway projects in engineering and operations, Jörg Sielemann from ZF introduced the challenges and solutions with regard to heterogeneous multi-CAD environments and Petra Dlugosz and Alfred Eckrich gave insight into the current JT application at Bosch as well as the next steps.

Prof. Alfred Katzenbach, who guided the audience through the day, could not hold back his excitement with regard to the provided information. In his interim-conclusion he pointed out that one can clearly see that different companies address challenges in a different way and are at different states of their transformation, but the adoption rate of JT in industry is amazing.

After all the presentations from manufacturers and suppliers from different branches, the 180 participants could additionally experience an impressive handshake of two major IT vendors. Adrian Lannin from Microsoft and Mike Zink from Siemens PLM introduced the bridge between Physical and Digital with JT and 3MF. 3MF enables 3D printing at its best and is a pragmatic approach far beyond the capabilities of formats such as STL, OBJ or AMF. In the very near future it will also support 3D scanning. Siemens PLM will offer a JT-to-3MF converter in future. JT is the downstream format, and the special requirements for 3D printing are addressed by the 3MF format. An ideal combination, a success story for realizing openness fast and flexible, and a huge benefit for industry.

The final presentation of the day was given by Rudolf Dotzauer and Dr. Sebastian Handschuh. The two project chairs summed up what was achieved in the past. It is impressive what was realized by the projects. But even more impressive is the fact that the presenters today show that their companies really take advantage out of these results. That’s the real success story! And the two chairs underlined, that the projects are no closed shops. Interested companies are welcome.

With 50% more participants than at the first JT Day in 2015 this day was really exciting. And people did not only come to the Continental Arena in Regensburg (Germany) because of the excellent presentations. Within the breaks one could see people networking and informing themselves about products and services of the IT Vendors who were represented in the exhibition space: CoreTechnologie, :em, Kisters, PDTec, PROSTEP, Siemens PLM, SSC, TechniaTranscat, Theorem and T-Systems.

Final remark: Beside all IT, business etc. there was one thing which was accompanying the participants through the day. And as the conference location was a soccer stadium, guess what? A trophy! But not a simple one, a smart one. In his opening keynote, Thomas Buck took it as the subject of his Live-VR-Demo. Of course, it was modeled in JT. And at the end, every presenter got personalized 3D-print of it. You see, IT events can be vivid.

My special thanks to the team who helped to make this event happen, to the speakers, to the exhibiting companies and – of course – Continental.

Leave a Reply

Want to join the discussion?Feel free to contribute!